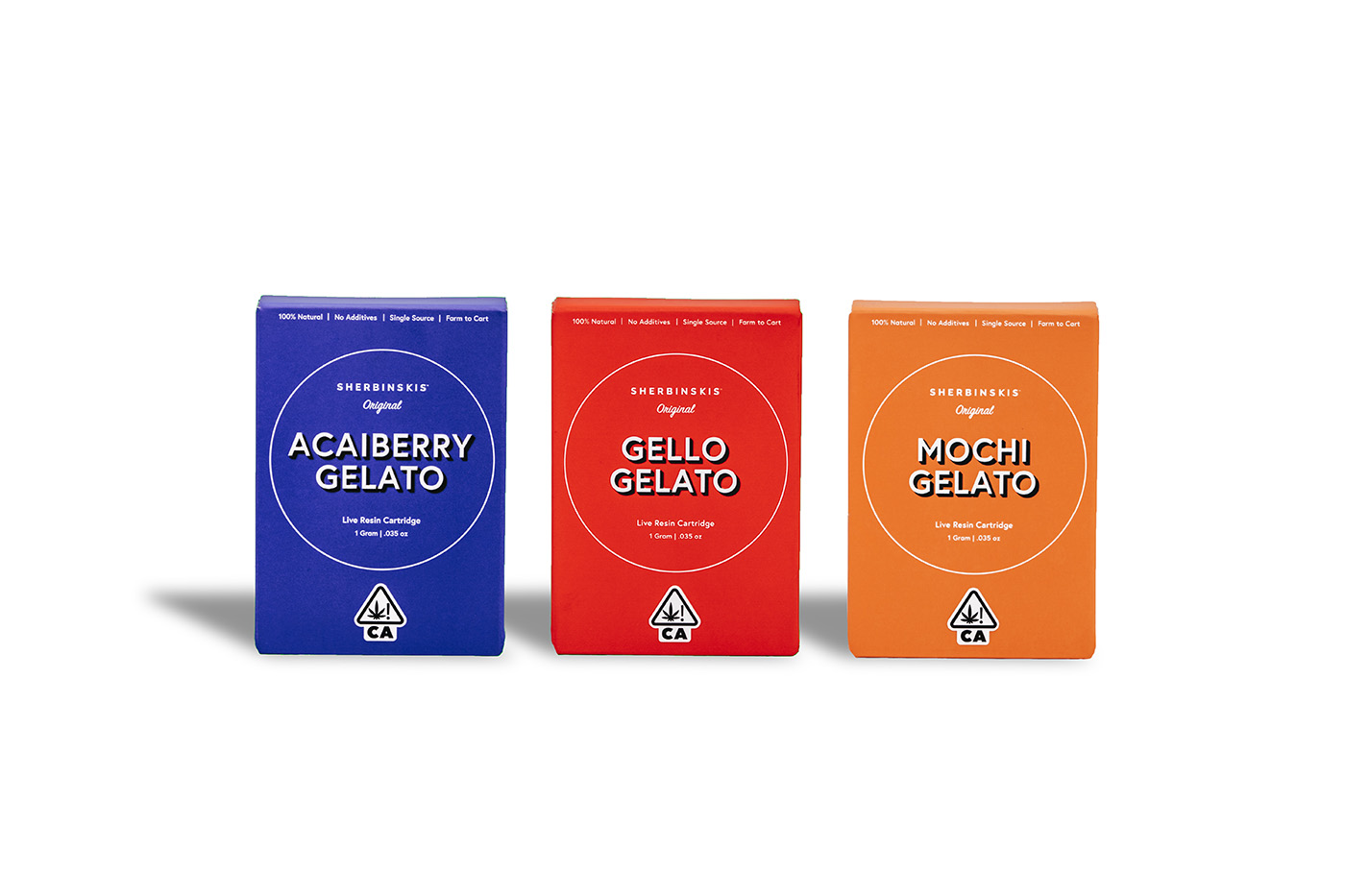

Step into a cannabis retail store, and you’ll find one of several scenes. You may see shelves and display cases filled with eye-catching, colorfully branded mylar pouches, paperboard boxes, and glass and plastic jars. Some packaging may even give a peek at the flower inside. In other stores, understated, uniform, opaque packaging with brand names and basic information punctuated by the universal THC symbol create a minimalist vibe that’s not quite Apple-level sophisticated but uses familiar brand names to guide purchasing decisions. These days, you may not even step into a dispensary at all if you can shop from home and have your products delivered in plain outer packaging.

All of the above scenarios are equally likely, depending on where you are in the United States. The fractured U.S. retail cannabis landscape creates all sorts of headaches for brands, especially those working to build a strong presence across multiple regions. Add in the pressure of price compression, and it’s easy to understand why some brands fall back on treating packaging as an afterthought, especially in more restrictive markets.

However, brands lose valuable opportunities to connect with consumers, set the tone, and build anticipation when they approach packaging solely as a compliance– or cost-driven decision. And once the product is open, interior packaging details can make all the difference in product perception and experience. From graphics to physical design and materials, all these elements telegraph important brand values that extend to the product itself. At the end of the day, consumers want an experience, and packaging is an important facilitator in achieving that goal.

“Packaging is the physical manifestation of the brand as much as the product itself,” said Kary Radestock, chief executive officer at Hippo Premium Packaging. “Well-designed packaging expresses the brand and sets the experience, but it also has to be child-resistant, tamper-proof, compliant, and designed to protect the product. It has a lot of heavy lifting to do for such a little thing.”

Many companies, especially smaller operators, may be tempted to go it alone on packaging, using designs from Fiverr and low-cost mylar bags from overseas vendors. However, working with an expert packaging partner can offer cost-saving strategies at every step while producing designs that help drive premium pricing. Furthermore, an experienced packaging partner will have in-depth knowledge of compliance, child-resistant design, and other requirements, helping to avoid costly mistakes in the industry’s ever-changing regulatory landscape.

Brandworthy for the shelf and screen

First impressions matter. This is a reality Elizabeth Corbett, AE Global’s president of enterprise sales, knows from experience working in the spirits world. “Seventy percent of wine is purchased the first time based on the label design or the shape of the bottle,” she said. “And if you pick that bottle up, you are 50 percent more likely to purchase it, which I find quite interesting.”

Initial impressions become more challenging in cannabis retail. Product packaging frequently is displayed on shelves behind counters—or sometimes isn’t displayed at all—and products are not handled by most consumers before purchase.

Online menus create a completely different set of challenges. Depending on the product category and retailer, online photos may show only the product—not the jars, boxes, tins, or pouches containing it. However, even if the online menu shows only a lone pre-roll or tidy jar of rosin on a white background, the brand name is right there beside it influencing customer purchasing decisions.

How can companies build brand awareness in a highly regulated space? Given the restrictions against advertising, packaging remains one of the most effective ways to connect with consumers.

Sasha Kadey, chief marketing officer at Final Bell, knows the challenge well, having recently worked on Cookies’ upgraded packaging as part of the brand’s global expansion. Kadey recommends brands visit retailers early in the package-design process to envision how different concepts might perform on the shelf. A mindfully created brand book can be invaluable at this stage for keeping the aesthetic disciplined and focused.

Packaging manufacturers also can help guide the process with deep knowledge of materials and formats that will align with a brand’s vision and core values, whether those include sustainability, novelty, activism, or culture-driven vibes.

“Many companies are run on triage, and marketing is often one of the first things to be cut,” Kadey said. “When it comes to packaging, though, there are three things that balance out, and those are budget, creativity, and scale. Some brands may have a small budget and small scale, but they have incredible creativity that allows them to take stock packaging and turn it into something that’s really brand-appropriate and compelling. Other brands may have the scale and budget but not the in-house creativity. For those brands, it makes more sense to partner with an outside design firm that can add the missing part of the recipe.”

According to eBottles CEO Robert Lerman, “You want consumers to recognize your brand based on the packaging alone. In some cases, they may not even remember the exact brand name, but they will remember what the package looked like and that the product delivered an experience they loved.”

Impact beyond store shelves

While brands may think of packaging potential only in the context of shelf display, the interaction between consumers and packaging can play an outsize role in creating a positive brand experience and building brand awareness. That’s one big reason packaging is important even when products are purchased online and delivered.

“Don’t cheat your customer out of the brand experience,” Radestock said. “Some companies will cheap out when it comes to delivery products because they think the packaging doesn’t matter, but you know what? I buy makeup products directly from Chanel in part for the experience. My order comes in a beautiful, embossed box with a personalized packing slip in a die-cut sleeve. It’s so well-executed, it reinforces the quality the brand stands for.”

According to Brad Nelson, director of marketing at LeafLocker, a division of All Packaging Company, “We’ve seen brands initially plan to use the cheapest option, believing packaging won’t make much difference, but the packaging drives that first interaction with the brand. If it’s not a pleasant experience, the brand might not get a second chance.”

As summer concerts, festivals, and other social events gear up, many products are destined not for home enjoyment but for use on the go. This is fueling the rise in packaging designed for “pursability and portability,” a trend reflected in the rapidly growing 0.5-gram multipack pre-roll category.

“Consumers want packaging that doesn’t look like medicine,” Lerman said. “They want it to be a cool experience when they share a pre-roll with friends.” He compared the experience to bringing a nice bottle of wine to a dinner party.

Today’s millennial and Gen Z consumers also are more likely to share product unboxing on social channels, eagerly highlighting mindful touches like embossing, unique graphics, or a thoughtfully placed message on the interior. For sustainability-driven brands, the packaging material itself often is the feature. Consumers are eager to share they are in the know when it comes to reclaimed ocean-bound plastics, recycled materials, or hemp.

As brands conceptualize packaging, they should keep in mind how the various forms and materials will play in consumers’ hands and how the experience will reinforce brand identity and product quality. How will an unboxing livestream look on TikTok, for example? If the consumer shares with friends during a lazy summer picnic, what types of conversations will the packaging spark? For those consumers who prefer to partake at home, how will the packaging add to the ritual? Questions like these can lead to special touches that may elevate the experience.

Compliance and child-resistant design

Child-resistant packaging, tamper-resistant packaging, opaque packaging, and extensive label requirements all limit a brand’s ability to create continuity across different product categories and marketplaces. They also impact the consumer experience, making a carefully planned compliant design more important than ever.

“Sometimes there’s a disconnect between the brand’s vision and the packaging due to all the different rules and regulations,” Kadey said. “When designing cannabis packaging, you have to consider the warning symbols and labels that must be included, which can be very long and cumbersome. It’s a unique challenge when compared to traditional [consumer packaged goods].

“The Cookies flower tub, a simple vessel for flower, is a great example of how brands can build continuity while also meeting different rules and regulations,” she continued. “We designed one transparent blue version with the Cookies logo molded into the lid and tub. Another version is opaque blue with the logo molded into the lid and tub. And then we designed a version for Canadian markets that is all opaque with no logos.” The three designs create a cohesive packaging strategy across very different regulatory landscapes.

Experienced cannabis packaging companies can be invaluable partners to brands of all sizes when it comes to navigating complex state regulations and remaining compliant. Corbett knows the challenges well. “I’ve been working with a customer who is entering Missouri, but one of their logo elements doesn’t comply with state regulations,” she said. “Their logo is a really important part of the brand identity, though. We’ve been working on packaging strategies that will honor the brand and maintain a strong identity while still meeting the state regulations. That’s a challenge all in itself.”

Not only must the design be compliant, but packaging also must meet stringent child-resistant regulations that likely will receive increased scrutiny following the January 2023 publication of National Poison Data System surveillance data showing a 1,375-percent jump in children under six who accidently ingested cannabis from 2017 to 2021.

Eyad Aboabdo, co-founder and vice president at Chubby Gorilla, has years of experience working with regulations from around the world, including packaging for nicotine e-liquids as the products shifted to compliant packaging requirements under the Child Nicotine Poisoning Prevention Act of 2015. “Chubby Gorilla was one of the first packaging companies to be compliant with that act, because we had already designed and tested our packaging to those standards,” Aboabdo said. He pointed out packages that seem hard to open still don’t necessarily meet the requirements set forth by the Poison Prevention Packaging Act of 1970, 16 CFR 1700, and other regulations that define child-resistant-packaging testing requirements. Aboabdo noted many of the regulations require packaging to be senior-friendly as well. Make the container too challenging to open, and a company could be in compliance for one age group and out of compliance for another.

As the industry matures, packaging companies are investing in more sophisticated child-resistant designs that improve consumer experiences while meeting stringent regulations. For example, LeafLocker’s child-resistant, 100-percent-paperboard boxes open with the push of a paper button that releases a customized inner tray without the typical box wrangling, building a positive consumer experience from the initial interaction. N2 Packaging Systems recently designed a one-piece child-resistant lid that clips directly onto the company’s metal cans, making it easier for consumers to reseal the container after opening.

Preserving product integrity

A brand’s packaging may be both eye-catching and compliant, but if it fails to protect the product across its lifecycle, then the brand risks losing consumers. Anyone who’s opened a package of dry, crumbly flower knows the disappointment.

When searching for a packaging partner, keep in mind everyone will have a pitch for why their containers are better for product quality and how they are innovating new lids, seals, and other solutions to offset the challenges of packing, transporting, and retailing a uniquely perishable product. For example, N2’s metal cans are packed with flower, filled with nitrogen, and hermetically sealed to prevent moisture and terpene loss due to oxygen or ultraviolet exposure, a feature that could be especially intriguing for producers in arid regions. Taking a different approach, eBottles offers glass jar options with heat-seal foil liners and the addition of blotter paper with a drop of terpenes to help prevent terpene loss when the jar is opened. “The additional terpenes fill the head space of the jar, so the natural terpenes stay in the flower,” Lerman explained.

Needless to say, when interviewing potential packaging partners, it’s important to ask for hard data on claims about packaging performance and even do one’s own shelf-stability tests, if possible. Packaging companies also should be able to answer product-safety questions such as what types of food-safe can or bottle linings are being used to prevent leaching of polyfluoroalkyl (PFAS) substances or heavy metals into products.

Embracing sustainability

Cannabis consumer demographics are shifting rapidly, with millennials currently dominating and legal-age Gen Z consumers gaining market share each year. Young, savvy consumers favor brands that incorporate sustainability into their missions. Multiple studies indicate younger adults will select a sustainably grown, manufactured, or packaged product over its conventional counterpart even if it means paying more. One caveat: These same consumers expect transparency and honesty, and they will call out brands that treat sustainability as a marketing gimmick rather than a core value.

The push for sustainability is coming from regulators, as well, with an increasing number of states adopting well-intentioned sustainability guidelines for packaging. “We’re seeing really good efforts in states like New York, where they put a lot of thought into sustainability before the market opened,” said James Eichner, co-founder and chief security officer at Sana Packaging. He anticipates sustainability-driven requirements will expand as other states come online and more mature markets like Colorado work to reduce cannabis’s environmental footprint.

“One of the first things we do with new customers is define what sustainable packaging means to them, ask them what they care about, and make sure they understand the tradeoffs with different types of materials,” Eichner said. “All materials have upstream and downstream tradeoffs. For example, metal and aluminum have the highest rate of recycling, but the extraction of metal and creation of the material can be very damaging to the environment. In this case, you have a good tradeoff with recycling but a bad tradeoff with material sourcing. There are similar tradeoffs with every type of material.”

Corbett said, “When it comes to sustainability and packaging, I’ve been doing this for a long time. I’ve worked with corporations like Starbucks and Nordstrom that have major sustainability directives, and I’ve sat in meetings where someone asked, ‘What’s the one way we can be the most sustainable?’ My answer was, ‘There is no one way.’ You have so many different things you can do to make a positive impact. Evaluating structure size, how it is produced, where it is made, recycled content, and recyclability all can have significant impacts on your sustainability platform.”

Eicher agreed there’s no one right way to be sustainable. “Sustainability can feel slippery, but companies should think of it as an opportunity for a more honest and frank conversation about the options out there and the tradeoffs with each one,” he said. “So often with sustainability, people want to slap on a Band-Aid fix or just use a buzzword, but that’s not a solution at all. On the other hand, there’s a missed opportunity for brands to stand behind their packaging decisions and have an honest conversation about the decisions they made and why they’re important to the brand.”

He pointed to Patagonia as the gold standard for how brands can authentically incorporate sustainability into their stories. “I’m sure if you talked to an executive at Patagonia, they would outline all their sustainability efforts that are working well, all the things that aren’t so great, and how they’re planning to address the problematic things over the next few years.”

What does it look like when a brand goes all in on sustainability?

Radestock shared her recent experience working with Harmony Extracts, the Colorado licensee for Garcia Hand Picked. “Harmony Extracts is very close with the [Garcia] family and really cares about the Jerry Garcia name and what he stood for,” she said. “They developed a line of beautiful, high-quality organic products, and it was important to them to bring that same dedication to packaging. We worked closely with them for months to ensure all package components, including the inks, were petroleum-free. Tincture bottles were another challenge, since most tincture bottles have a plastic liner on the inside, but the brand insisted on a plastic-free bottle. We had to really push our suppliers to get where this brand wanted to go, and we’re really proud of the final result.”

Not all brands have the budget or scale to create custom sustainable packaging solutions, but there are meaningful steps brands can take to improve sustainability practices while also lowering costs.

Finding a partner

When it comes to finding a packaging partner, approach the process with the mindset of seeking a service provider, not just a faceless source of boxes, jars, or pouches. Just like packaging can be considered one piece of the product, a brand’s packaging partner should be considered a trusted member of the team that is committed to the product’s success.

The right packaging partner will be eager to understand the company’s vision and budget and find options that help control costs, such as offering multi-product minimum order quantities for smaller runs.

Once a brand has signed on with a packaging company, Corbett recommends starting with the target cost of goods and working from there. This quickly can whittle down an overwhelming number of choices into a handful of meaningful options that tick all the boxes when it comes to brand identity, compliance, sustainability, and return on investment. The approach also reduces time lost on designing a packaging solution that ends up being out of scope with product cost.

“I once worked with a CPG company that had partnered with an outside design firm to develop a high-end coffee club concept,” Corbett said. “When we received the packaging design, we quickly realized there was an issue. The brand’s target cost per unit was $1.50, but the packaging alone would run around $4 per unit due to its complexity. There was a huge disconnect.”

Aside from unit cost, an astute packaging partner also will help find solutions for nuts-and-bolts operational details that can be critical to controlling costs.

“Brands will want to keep the big picture in mind when looking at packaging,” Nelson said. “There’s the unit cost, of course, but they also need to factor in any setup costs, one-time tooling costs, or other onboarding costs. Freight is another area brands may overlook. Is freight included in the unit cost, or is it a separate itemized cost, and how accurate is the projection?”

Companies also should consider how packaging fits with their operational practices. “A lot of people focus only on the unit price of packaging and don’t take into account how much it will cost to pack out, especially if they are hand-packing,” Kadey said. “We always ask for these details early in the process and, from there, we’re going to eliminate packaging styles that are not compatible with the company’s operations.”

Nelson noted even with automated systems, companies need to be aware of potential issues. “For brands that are running boxes through automated equipment, the box has to be perfect or it won’t run through the equipment properly,” he said. “We have our structural engineers meet with customers and ask for the make and model of their equipment so we can design a carton that will work for their system.”

Aside from avoiding unexpected costs, long-term packaging partners also may add value when forecasting future needs—an especially important consideration in light of never-ending supply chain crises. “We work closely with our customers to forecast their packaging needs,” Aboabdo said. “If it’s a client who has been with us for a while, we understand what their needs are and may even hold some extra inventory for them.”

Preparing for the future

Many packaging companies already are preparing for eventual federal legalization, optimistic that consistent regulations across states will allow for greater efficiency and sustainability. By building relationships with experienced packaging partners now, brands can ensure they are well-positioned for the rush of new opportunities that will come as a result.

5 Tips for Making Your Packaging More Sustainable

When it comes to sustainable packaging, not all companies have big budgets. Even for those that do, return on investment must be taken into account. However, brands of all sizes can follow these tips to reduce environmental impacts.

Define what sustainability means to your brand.

Sustainability is a broad term that can encompass everything from ethical sourcing to carbon neutrality, and packaging is only one piece of the puzzle. Regardless of how sustainability fits into your mission, opportunities exist to reduce your company’s environmental impacts.

Consider the entire packaging life cycle, from where raw material is sourced all the way to what happens once the package is tossed.

There is no perfect packaging solution; all materials have tradeoffs. When considering options, ask the following questions: How energy-intensive is it to source and transport the raw materials and finished products? How likely is it that discarded packages will be recycled? If the packaging ends up in a landfill, how long will it take to break down, and are there any negative environmental impacts?

Opt for packaging made from recycled, reclaimed, or plant-based materials.

The old mantra “reduce, reuse, recycle” has evolved into a more nuanced “circular economy” concept, but the bottom-line goal remains the same: to reduce waste, efficiently use resources, and maximize product life cycles while minimizing environmental impacts.

Right-size your packaging.

Right-sized packaging is another way to reduce waste, with the added benefit of trimming shipping costs due to smaller package size and weight. Packing materials used during shipping make a difference as well. Steer clear of polystyrene foam peanuts and other petroleum-based plastic materials whenever possible, opting instead for plant-based alternatives.

Set realistic timelines for the design and manufacturing process.

Plan on four to six months for packaging design, manufacturing, and shipping, depending on the complexity of the design. A realistic timeline reduces the risk of expensive expedited shipping that could involve carbon-intensive air transport