In recent years, the vaping industry has seen the emergence of both mesh and ceramic coils as an innovative alternatives to traditional metal-coil-based heating elements. Today we’ll delve into the details of ceramic coils, their potential advantages and disadvantages, compliance with the Tobacco Products Directive (TPD), and concerns surrounding silica dust.

What are Ceramic Coils?

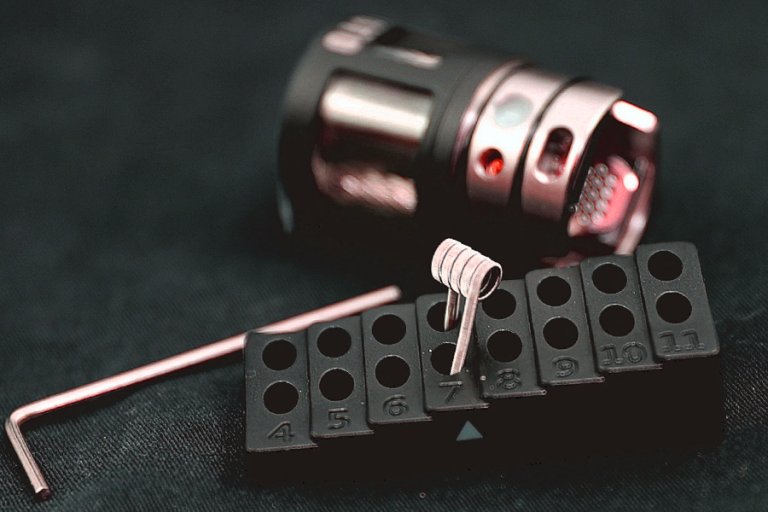

Ceramic coils are heating elements in electronic cigarettes and vaporizers that use a ceramic material, typically porous, as the core component of the coil. The ceramic material is wrapped with a thin wire, usually made of Kanthal, Nichrome, or Stainless Steel. As electricity flows through the wire, it heats the ceramic core, which in turn vaporizes the e-liquid absorbed into the porous ceramic material.

Advantages of Ceramic Coils

Enhanced Flavour and Vapour Production

One of the primary benefits of ceramic coils is the improved flavour and vapor production. The porous ceramic material evenly distributes heat, leading to consistent vaporization of the e-liquid. The ceramic core also prevents direct contact between the e-liquid and the metal wire, reducing the likelihood of dry hits and burnt taste. As a result, ceramic coils often provide a smoother and more flavourful vaping experience.

Longer Lifespan

Ceramic coils tend to have a longer lifespan than traditional coils due to their resistance to heat and chemical degradation. The ceramic material can withstand high temperatures without breaking down or warping, which translates to a more durable and long-lasting coil.

Disadvantages of Ceramic Coils

Slower Ramp-Up Time

One potential drawback of ceramic coils is their slower ramp-up time compared to traditional coils. Because ceramic materials have a higher thermal mass, they take longer to heat up and reach the desired temperature for vaporization. This slower ramp-up time can lead to a less satisfying initial vaping experience, particularly for users accustomed to the instant heating provided by traditional coils.

Inconsistency in Quality

The quality of ceramic coils can vary significantly depending on the manufacturing process and materials used. Some ceramic coils may have a rough or uneven surface, which can impact the coil’s performance and longevity. Users may experience differences in flavour, vapour production, and coil life even when using ceramic coils from the same manufacturer.

TPD Compliance for Ceramic Coils

The Tobacco Products Directive (TPD) is a set of regulations implemented by the European Union to ensure the safety and quality of tobacco and related products, including e-cigarettes and vaping devices. Compliance with TPD requirements is crucial for any product to be legally sold within the EU market.

Currently, there is no specific TPD requirement that directly addresses ceramic coils. However, manufacturers must ensure that their products, including ceramic coils, meet the general safety and quality requirements laid out by the TPD. This includes submitting a detailed notification to the relevant authorities, providing information on the materials used, manufacturing processes, and any potential risks associated with the product.

Silica Concerns

One concern associated with ceramic coils is the potential release of silica dust during vaping. Silica, a common component in ceramic materials, can pose health risks when inhaled in the form of fine dust particles. Inhaling silica dust can lead to silicosis, a chronic lung disease caused by the accumulation of silica particles in lung tissue, resulting in inflammation and scarring.

However, it is essential to note that many ceramic materials contain no silica and pose no risks. The manufacturing process and the quality of the ceramic material play a crucial role in determining the potential for silica dust exposure. High-quality ceramic coils made from well-controlled processes are very unlikely to pose significant risks. Moreover, many ceramic coils on the market use a non-silica ceramic material, which reduces the potential risks for silica to zero.

Conclusion

Ceramic coils have emerged as an innovative alternative to traditional metal-based heating elements in vaping devices, offering several advantages, such as enhanced flavour, vapor production, and longer lifespan. However, they also present some drawbacks, including slower ramp-up time and inconsistent quality.

Although there are no specific TPD requirements that directly address ceramic coils, manufacturers must ensure that their products meet the general safety and quality standards laid out by the directive. Concerns surrounding silica dust and its potential health risks have been raised, but the likelihood of exposure to silica dust depends on the quality of the ceramic material and manufacturing processes.

As the vaping industry continues to evolve and innovate, it is essential for manufacturers to prioritize safety and transparency in their products, and for users to make informed choices when selecting and using vaping devices and components.